a. Working Temperature: -20℃ to 80℃

b. Frequent Switching does not affect life time

c. Instant light on, similar to that of incandescent lamps

d. Negligible maintenance cost ( long life, over 50 Khrs)

e. 0-100% dimmability, without affecting lamp life

f. Parallel operation: space saving and common inverter

![]() Full Compliant to latest Environment Regulations:

Full Compliant to latest Environment Regulations:

European Union approved RoHS compliance regulation in November 2002, it regulates the use of lead, Nickel, Mercury, Chromium and etc in 10 categories of electronic and electrical devices from July 2006 onwards. From the year 2018, the mercury content figure of any fluorescent lamp below 30W rating shall be reduced to 3.5mg or lesser, while its life span published shall be at least over 20,000 hrs. The mercury content inside CPFL lamp is within 1.6-3mg range which is much lesser than the latest RohS requirement. Its production does eliminate any application of lead and toxic materials. The "Minamata Convention on Mercury" agreement co-agreed by more than 140 countries which including EU’s countries, P.R. China and Taiwan, only allows less than 5mg mercury content (maximum) inside each any format of fluorescent lamp in 2021. So CPFL fully complies in a way far less than the requirement.

Conventional FLs requires preheating the filament and the resulting ion sputtering causes electrode oxidation as well formation of amalgam of mercury compound. A CPFL, on the other hand, does not oxidize. Nor will the CPFL form mercury amalgam. And our CPFL has achieved a lifespan as long as 50,000 hours.

The conventional FLs require high starting voltage and heating filament, and hence the tube temperature keeps increasing with times, which in turn lower the luminosity. The CPFL, on the other hand, maintains its dielectric constant across the ceramic electrodes over a wide temperature range (-45℃ ~ 250℃).Consequently, a steady optical output.

As stated before, the ceramic electrodes do not react with mercury vapors and hence its optical output does not change because the mercury vapor does not diminish.

![]() CPFL, a green, long life and comfortable lighting Source

CPFL, a green, long life and comfortable lighting Source

CPFL only requires 1.6-3mg Hg (varies with tube length and/or diameter) which makes minimal harm to our environment and such ever lowest Hg figure is mostly acceptable by lots of new and strict environmental regulations. In contrast, T5 lamp and conventional fluorescent lamp which require additional 2-4 folds Hg content to compensate for the content loss owing to chemical amalgamation at heating filaments at both ends. Such "amalgamation" greatly reduces the lamp life, and additional Hg content makes harms to environment.

A tiny solid mercury cube (rather than liquid form) is injected into CPFL tube, it does not make harm to environment while on transportation and on the production line. CPFL features an over 5 years life hours so as its recycle span extends much longer than conventional fluorescent lamps and T5 lamps. The light spectrum emitted by CPFL is narrow and stable (same as T5 and conventional fluorescent lamp). CPFL does not produce any harmful and distressing blue light as LED does. Its remarkable characteristics of dimmability, RoHs compliance, lower total carbon footprint figurer, higher efficiency and comfortable light spectrum have been well recognized as a kind of new, green and technically innovative lighting source.

![]() High Efficiency and Luminousness

High Efficiency and Luminousness

Unlike the formation of plasma at CCFL & HCFL lamps, two opposite ceramic electrodes of CPFL creating an electric field across electric potential difference inducing stream flow of plasma. The harmonic motion of discharging-and-charging at ceramic electrode does not consume energy in theory, and perform very much like a working capacitor. The use of high dielectric constant ceramic effectively lower the working voltage and highly improve CPFL's efficiency and luminousness.

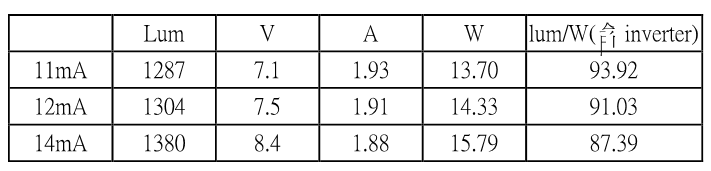

The following table exhibits the efficiency of sample CPFL lamps (one meter long and tube dia. 5mm) measured by a Taiwanese CCFL maker "Wellypower", the data reveal remarkable and superior result of CPFL.

Optical Efficiency Samples, taken in 2011 |

A CPFL does not need any ballast; instead it can be controlled with an inverter. In addition to its long life, CPFL can be connected in parallel to share the driving electronics. All these characteristic result in a lower overall cost.

CPFLs in parallel |

CPFL applications can be divided into general illumination and industrial illumination. In the general illumination arena, the CPFL can substitute all FL products available: light fixtures, spiral bulbs, and T-bar light source because of its long life, high optical efficiency and low operating temperature. In the case of T-Bar illumination, numerous CPFLs can be connected in parallel to reduce electronic cost.

Spiral Tube Light Bulb

T-Bar illumination with parallel CPFLs |

With the similar advantages, the CPFL can be used in a broad range of industrial applications; most noticeably the back panel light sources for the TFT-LCD panels. CPFLs can easily compete with the existing CCFL and EEFL because of its high luminosity and dimmability. Be able to power a number of CPFLs in parallel with a single inverter also makes CPFLs a prime candidate for the TFT-LCD light sources.

TFT-LCD |